TABLE OF CONTENTS

Introduction: The evolving need for Real-Time Asset Management

The days of manual logs, scheduled check-ins, and reactive maintenance are quickly being replaced by intelligent systems capable of providing actionable insights in real time. For companies managing distributed infrastructure, EV chargers, industrial equipment, smart buildings, or energy systems, the ability to track, analyze, and act on data across a growing network of assets has become both a strategic advantage and a necessity.

At Klika Tech, we’ve had the opportunity to work on several projects demonstrating how real-time asset visibility, enabled by edge computing and cloud integration, is not only transforming operations but also reshaping how teams plan, build, and deliver solutions.

This post shares what we’ve learned: the architectures that work, the pitfalls to avoid, and the leadership mindset needed to scale real-time data capabilities without overburdening teams.

The Core Challenge: Disconnected Systems, Delayed Decisions

Many companies operate with legacy systems or siloed infrastructures that result in:

- Delayed visibility: Events are only recognized hours or days later, hindering timely responses.

- Manual intervention: Field staff must physically inspect or reset devices, increasing operational costs and response times.

- Inefficient resource allocation: A lack of predictive insights leads to over-maintenance or missed failures, impacting uptime and budget.

- Lack of scalability: As the number of devices grows, the current system fails to scale linearly, creating bottlenecks.

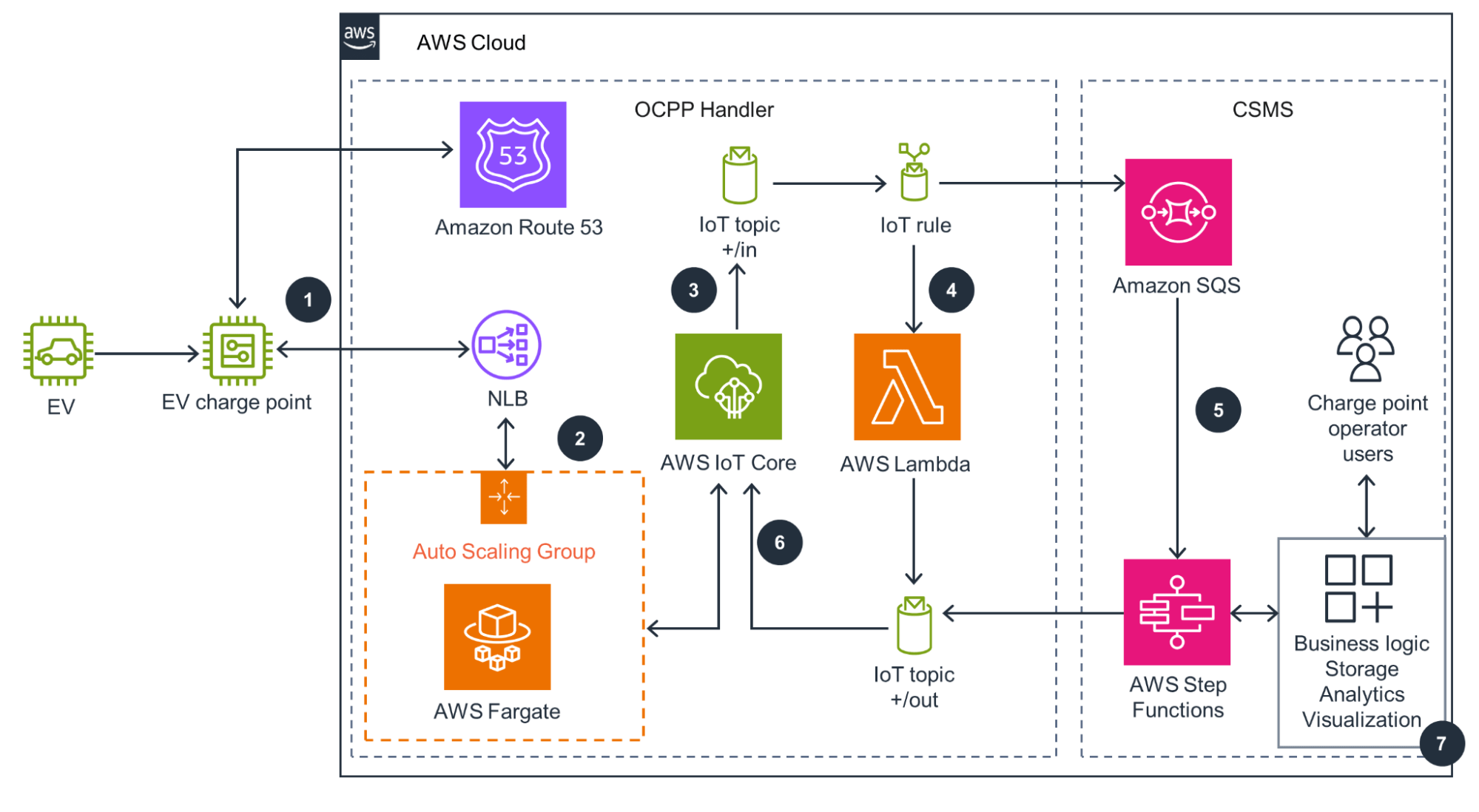

We saw this firsthand while working with an EV infrastructure provider where geographically distributed, OCPP-enabled chargers lacked real-time insight into charge availability, fault detection, and usage analytics for the operational team.

The Klika Tech approach: From Edge to Cloud

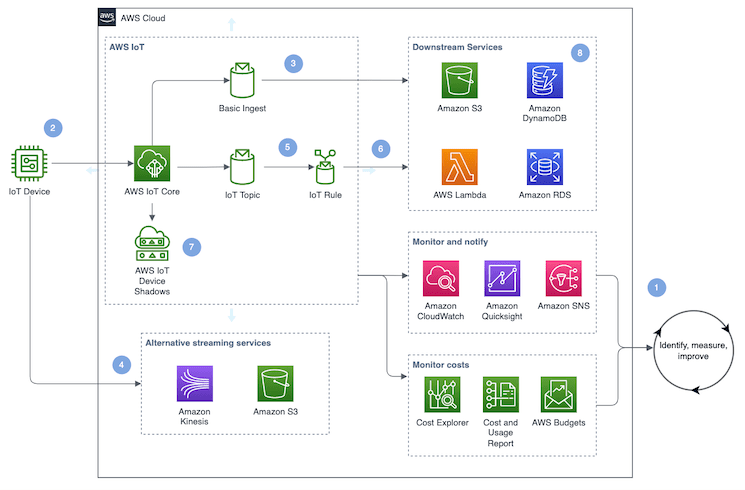

To solve these challenges, we designed and implemented an architecture that combined the strengths of edge computing with scalable cloud analytics. Here’s how we did it:

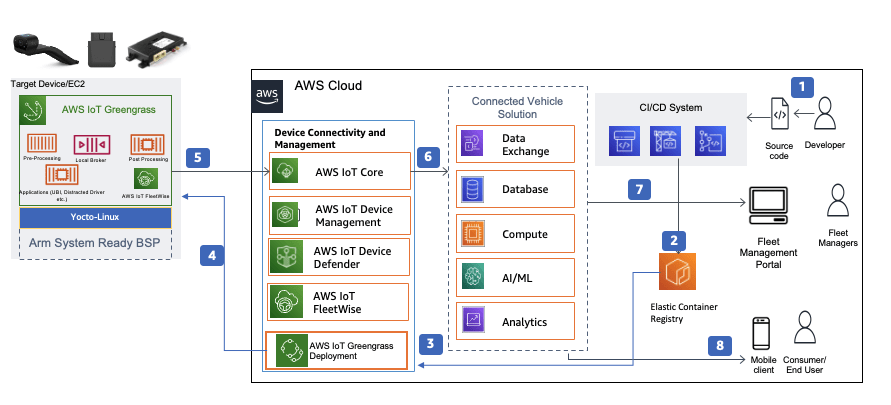

1. Edge Data Acquisition

Each charger was equipped with an embedded controller capable of running AWS Greengrass. This allowed for:

- Low-latency processing of critical data like voltage, temperature, uptime, and fault codes directly at the source.

- Efficient event filtering and normalization to reduce noise before sending data to the cloud.

- Local logic to execute commands, such as remote reboots or state resets, without waiting for cloud roundtrips, ensuring faster responsiveness.

2. Protocol translation via OCPP-to-MQTT Adapter

OCPP was the standard communication protocol for the chargers, but the cloud backend required MQTT for efficient messaging. We developed a custom adapter to translate OCPP messages into lightweight, structured MQTT topics that could be seamlessly streamed to AWS IoT Core. This approach:

- Simplified the cloud ingestion pipeline significantly.

- Made message routing more flexible and robust.

- Enabled easier integration with cloud-native services (e.g., AWS Lambda, DynamoDB, Timestream) for further processing and analysis.

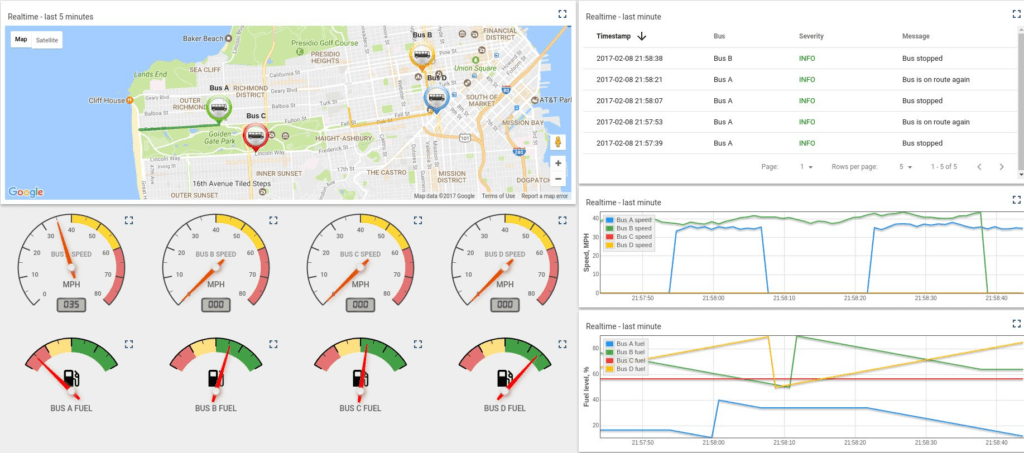

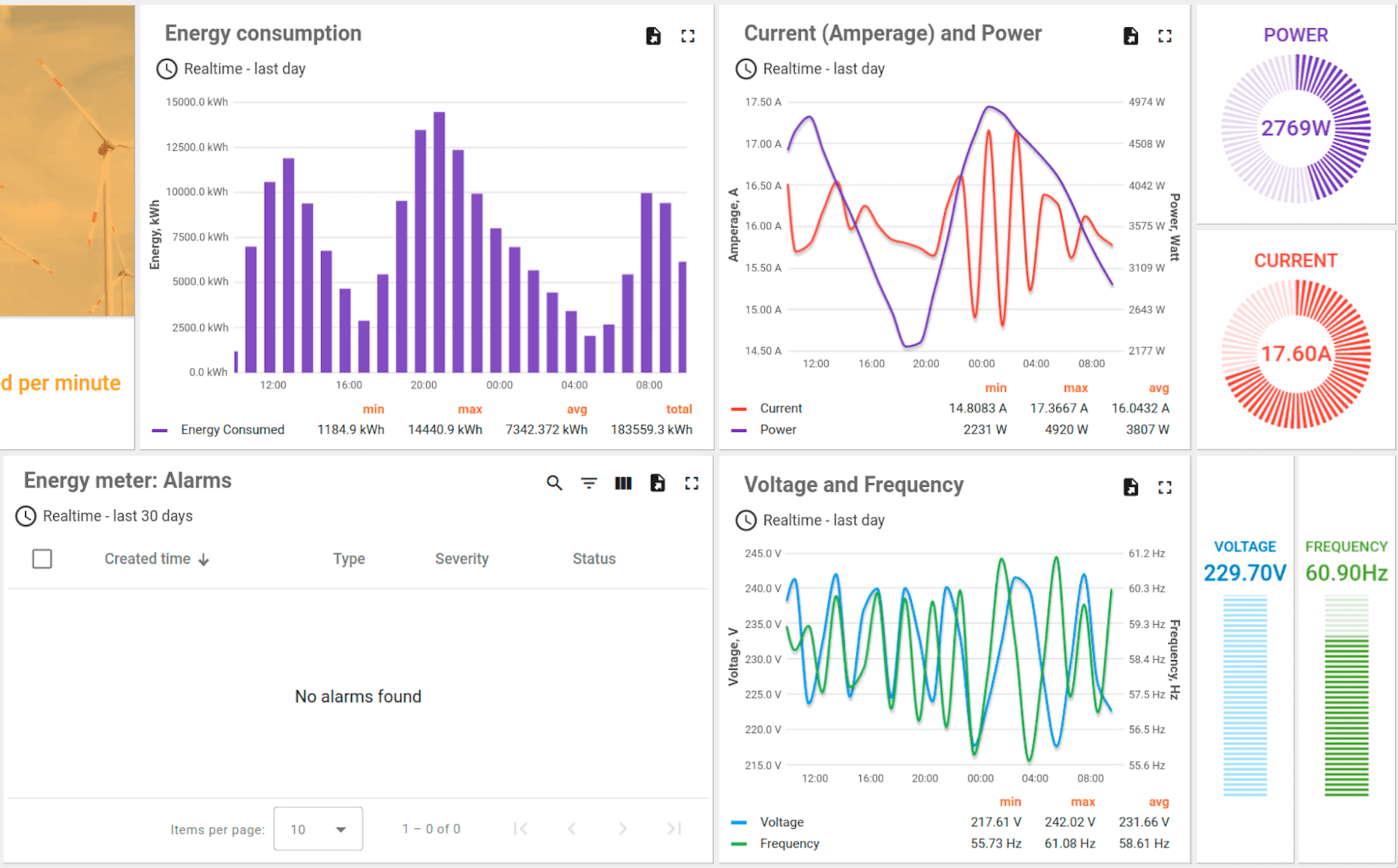

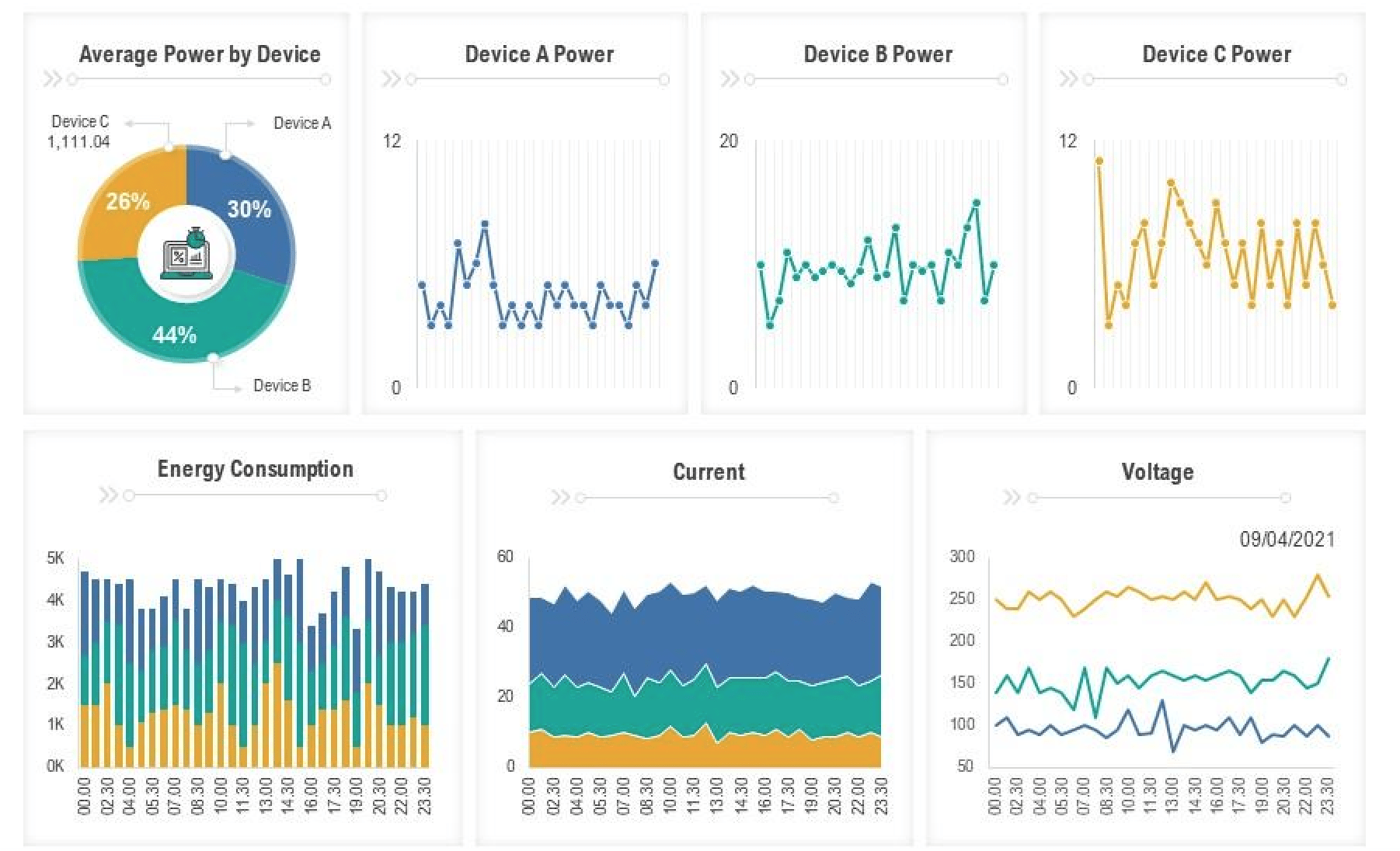

3. Real-Time dashboards & notifications

On the cloud side, we built a centralized asset management dashboard using AWS Amplify and a time-series database for querying trends. This empowered teams to:

- View charger status (available, in use, error) in real time.

- Analyze usage patterns by region or partner for strategic planning.

- Receive instant alerts for anomalies, such as overheating or failed sessions, facilitating proactive interventions.

Real-World Impact: Use cases in action

Our real-time asset management solution delivered significant improvements across several key areas:

Use Case 1: Predictive Maintenance for chargers

Using historical sensor data and edge-detected fault patterns, we can train ML models in AWS SageMaker to predict when a charger was likely to fail within the next 72 hours.

| Preventive maintenance | Condition-based maintenance | Predictive maintenance | |

| Likelihood of equipment failure | Medium | Medium | Low |

| Cost savings | 12-18% | 30% | 50% |

| Upfront cost | Low | Medium | High |

| Frequency of maintenance | At set time frequencies or meter readings | When a sensor detects a performance issue | Just before failure |

| Likelihood of predicting failure | Low | Medium | High |

| Technology required | Maintenance management software | Sensors | Sensors and maintenance management software |

| How parameters are set | N/A | Maintenance manager | Technology |

Impact:

- Reduced emergency technician visits by 30%, optimizing operational costs.

- Enabled scheduled maintenance based on real usage, not arbitrary intervals, improving efficiency.

- Improved SLA compliance for operators, enhancing service reliability.

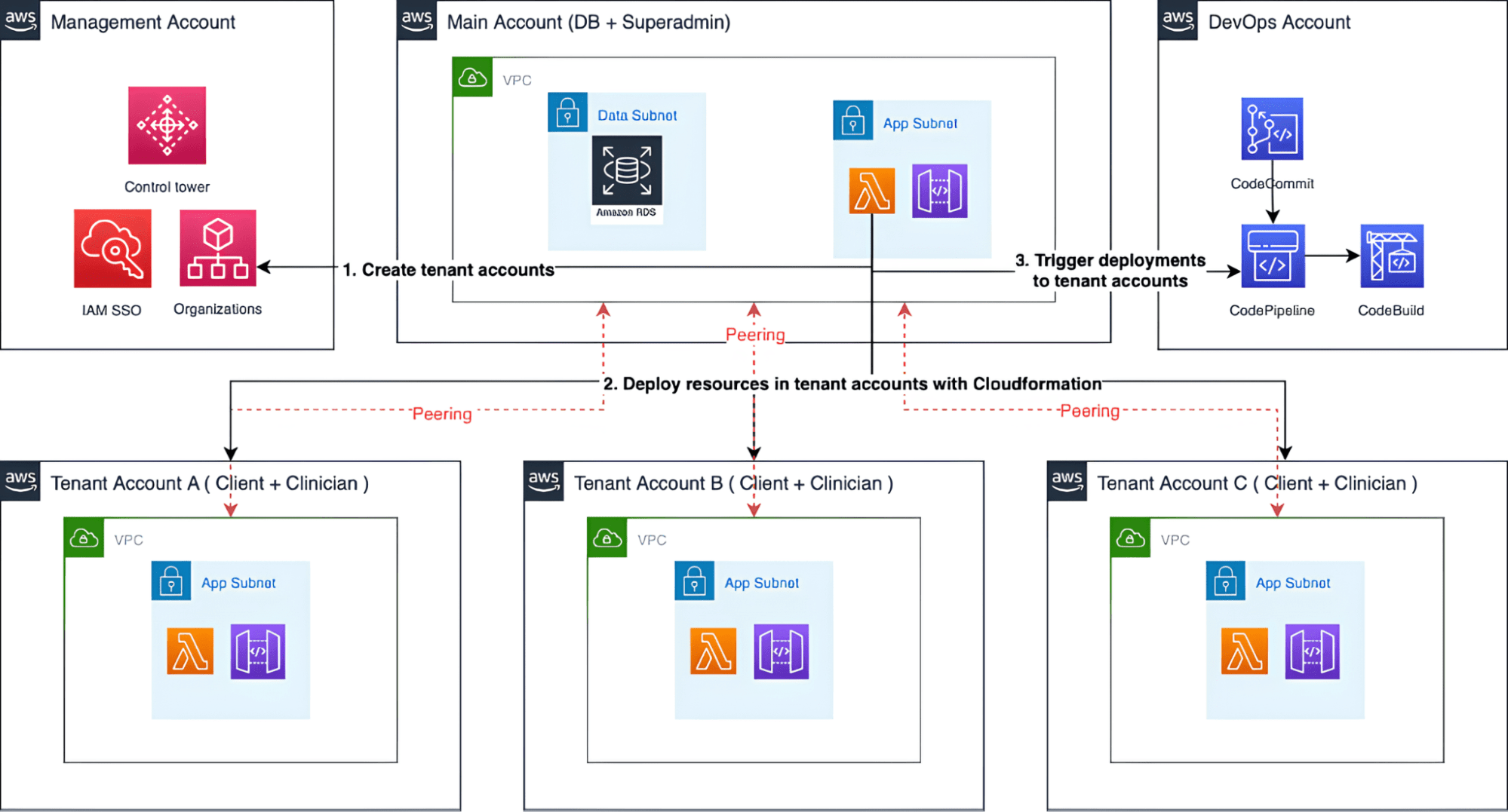

Use Case 2: Multi-Tenant operational visibility

One of our partners operated chargers across multiple white-label partners. We implemented tenant-aware data segregation and access control within the dashboard. This allowed:

- Each partner to view only their specific network, ensuring data privacy and relevance.

- Centralized control without compromising data privacy, streamlining management.

- Custom KPIs per tenant, such as energy delivered or uptime score, offering tailored insights.

Impact:

- Decreased support tickets due to enhanced partner-side transparency.

- Opened new upselling opportunities via actionable insights (e.g., usage-based tiering).

Use Case 3: Cost optimization through Event Filtering

In early deployments, edge devices sent every event—even those irrelevant to operations—to the cloud, inflating AWS IoT bills. We deployed an intelligent event filtering layer in Greengrass to:

- Drop redundant “heartbeat” messages and unnecessary data.

- Batch less-critical data for periodic transmission.

- Only transmit high-priority alerts immediately, ensuring critical information is prioritized.

Impact:

- Cut messaging costs by 45%, leading to significant operational savings.

- Reduced cognitive load on cloud systems, improving overall system performance.

- Helped the team scale confidently as the network grew, ensuring cost-effectiveness.

Leadership Perspective: Driving transformation without overload

Transforming asset management through real-time data isn’t just a technical initiative; it’s a leadership challenge. These projects taught us several key lessons:

1. Start with visibility, not perfection

Don’t aim to solve everything with AI from day one. Instead, focus on establishing basic visibility, what’s online, what’s failing, and what needs attention. Perfect data pipelines and advanced analytics can be iterated upon later.

2. Respect team capacity

We consciously avoided overwhelming the development team. Instead of pushing for fully automated AI alerts in phase one, we started with rule-based notifications and built up from there. This staged approach preserved delivery cadence and team morale.

3. Align outcomes with Stakeholder language

For the client, “reduced downtime” was more meaningful than “edge processing latency.” As managers, we consistently translated technical benefits into clear business outcomes. This clarity drove faster decision-making and stakeholder buy-in.

4. Empower teams at the Edge

Engineers closest to the field systems were encouraged to suggest filtering rules and edge logic improvements. This decentralized approach led to smarter, more practical decisions and increased team ownership.

Conclusion: Real-Time Data is the beginning, not the end

The transformation from traditional asset management to real-time intelligence is not just a systems upgrade; it’s a cultural and strategic shift. It demands that we, as leaders, empower our teams to think holistically, experiment safely, and scale thoughtfully.

At Klika Tech, we’re proud of the work we’ve done in this space, but even more excited about what’s next. From edge inference to cross-platform orchestration, the frontier is still evolving. And as we continue building for the future, one thing is clear: real-time isn’t a luxury anymore. It’s the new normal.

By Mohammad Shirazi, Portfolio Manager, Klika Tech, Inc.

Sources

- Internal project documentation and implementation

- Software-defined edge architecture for connected vehicles

- On Predictive Maintenance in Industry 4.0: Overview, Models, and Challenges

- Guidance for Modernizing Electric Vehicle (EV) Charging on AWS

- Internet of Things (IoT) Lens

- Cost-effective resources

- Predictive Maintenance

- Multitenancy in AWS with account per tenant Part-1

- Cost optimization tips for AWS IoT Workloads